RAJ CI (Fe - Ni)

RAJ CI (Fe - Ni)

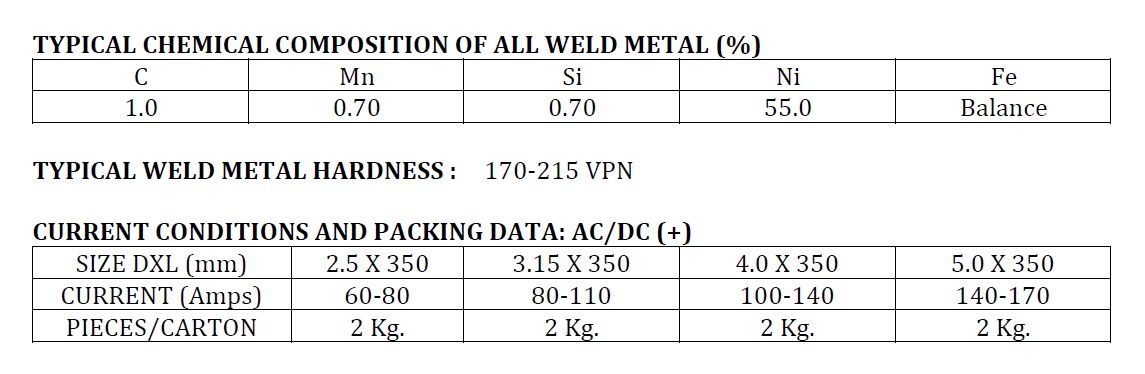

A Universal Nickel Iron alloy electrode for welding of cast iron.

CHARATERISTICS: RAJ CI (Fe–Ni) is a nickel-iron electrode designed to produce high strength, ductile and machinable weld with good colour match with the parent metal. Suitable for repair and joining components of various type of cast irons, including grey and nodular cast iron. Casting containing phosphorous levels higher than normal (approx. 0.2%) is more readily welded using this electrode. Due to the higher tensile strength and ductility of the nickel-iron deposits, satisfactory welds can be made on heavy and highly stressed sections.

APPLICATIONS: RAJ CI (Fe–Ni) is ideally suited for joining various types of cast iron such as grey cast iron, nodular cast iron, malleable cast iron, S.G. iron. For welding cast iron to steel and to nickel alloys, for filling and reclamation of various cast iron parts rectification of defective casting in cast iron foundry, engine heads, pump casing, impellers, rope drums, ingot moulds and a variety of cast iron machine parts and equipment.

Precautions:

- Redry the electrode at 150°C for one hour before use. Clean weld area free from any surface contamination. Bevel broken parts or cracks to 70 –80 ° Vee. Use a short Arc and as low a current as possible. Deposit short weld beads not exceeding 35-50 mm. Peen the welds to relieve internal stresses and allow the work piece to cool slowly to room temperature. Preheat the part if necessary.