STEELOMATIC-309 Mo 15

STEELOMATIC-309 Mo 15

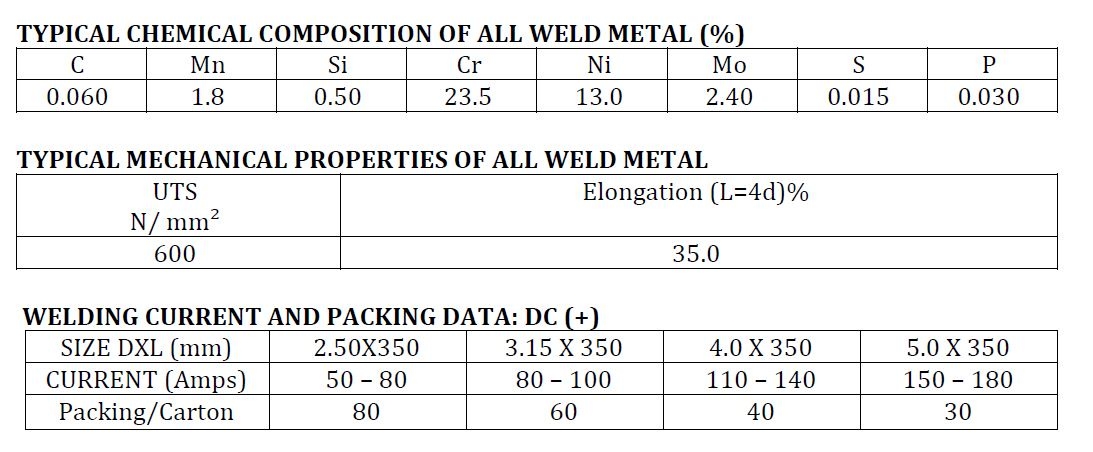

DESCRIPTION AND APPLICATIONS: STEELOMATIC – 309 Mo - 15 is a basic type all position electrode depositing 25Cr-12Ni-2.5Mo weld metal. It has pleasing operating characteristics. Radiographic quality weld metal posses excellent mechanical properties and oxidation resistance up to 1100 C.

Ideal for welding wrought and cast stainless steel of similar composition. For overlay application to resist from heat and corrosion. For joining dissimilar steels such as 18-11-Mo steel to mild steel, clad side welding of 18-11-Mo steels etc.

NOTES ON USAGE:

- Ensure that electrodes are dry enough. In case of moisture pick-up, ready the electrodes at 250°C for 30 to 60 minutes. Thereafter, either allow the oven to cool slowly to about 60° C, or transfer them to a holding oven maintained at 50°C – 60°C.

- Clean the joint faces to remove moisture, grease or any foreign matter.

- Employ welding currents within the prescribed range.

- Keep the arc as short as possible.

- Restrict weaving of electrode to within two and a half times the core wire diameter.

- Use stainless steel wire brush for cleaning the weld beads.

- STEELOMATIC-308

- STEELOMATIC-308 L

- STEELOMATIC-309

- STEELOMATIC-309 L

- STEELOMATIC-309 Mo

- STEELOMATIC-309 Mo L

- STEELOMATIC-309 Mo-15

- STEELOMATIC – 309 Cb

- STEELOMATIC-310

- STEELOMATIC-316

- STEELOMATIC-316 L

- STEELOMATIC-317 L

- STEELOMATIC-318

- STEELOMATIC-318 L

- STEELOMATIC-347

- STEELOMATIC-347 L

- STEELOMATIC – 410

- STEELOMATIC – 430