STEELOMATIC-347

STEELOMATIC-347

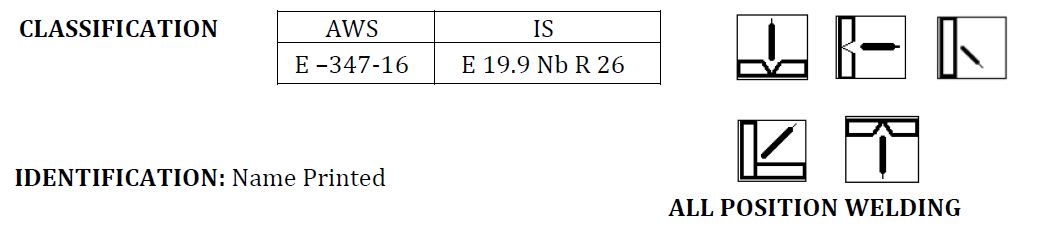

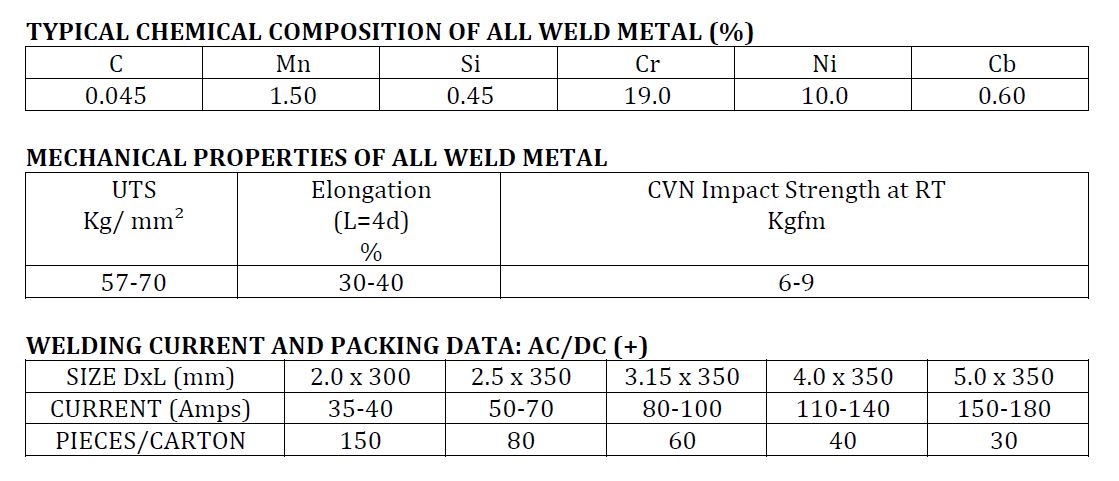

DESCRIPTION AND APPLICATIONS: STEELOMATIC-347 is a low carbon 19Cr – 10 Ni -.5Nb stabilized electrode with controlled ferrite content for max. resistance to creaking, corrosion and high temp. up to 800°C. Niobium prevents harmful carbide precipitation in the temp. range 425°-850°C. The electrodes has quite and stable arc extremely low spatter very easy deslagging smooth regular and finely rippled bead. It can be used for welding AISI 347, 321 and 304 steels and also for cladding carbon and alloy steels with suitable buffer layer. In the manufacturer of equipment for chemical food and aircraft industries.

NOTES ON USAGE:

- Ensure that electrodes are dry enough. In case of moisture pick-up, ready the electrodes at 250°C for 30 to 60 minutes. Thereafter, either allow the oven to cool slowly to about 60° C, or transfer them to a holding oven maintained at 50°C – 60°C.

- Clean the joint faces to remove moisture, grease or any foreign matter.

- Employ welding currents within the prescribed range.

- Keep the arc as short as possible.

- Restrict weaving of electrode to within two and a half times the core wire diameter.

- Use stainless steel wire brush for cleaning the weld beads.

- STEELOMATIC-308

- STEELOMATIC-308 L

- STEELOMATIC-309

- STEELOMATIC-309 L

- STEELOMATIC-309 Mo

- STEELOMATIC-309 Mo L

- STEELOMATIC-309 Mo-15

- STEELOMATIC – 309 Cb

- STEELOMATIC-310

- STEELOMATIC-316

- STEELOMATIC-316 L

- STEELOMATIC-317 L

- STEELOMATIC-318

- STEELOMATIC-318 L

- STEELOMATIC-347

- STEELOMATIC-347 L

- STEELOMATIC – 410

- STEELOMATIC – 430