STEELOMATIC-309 Mo

STEELOMATIC-309 Mo

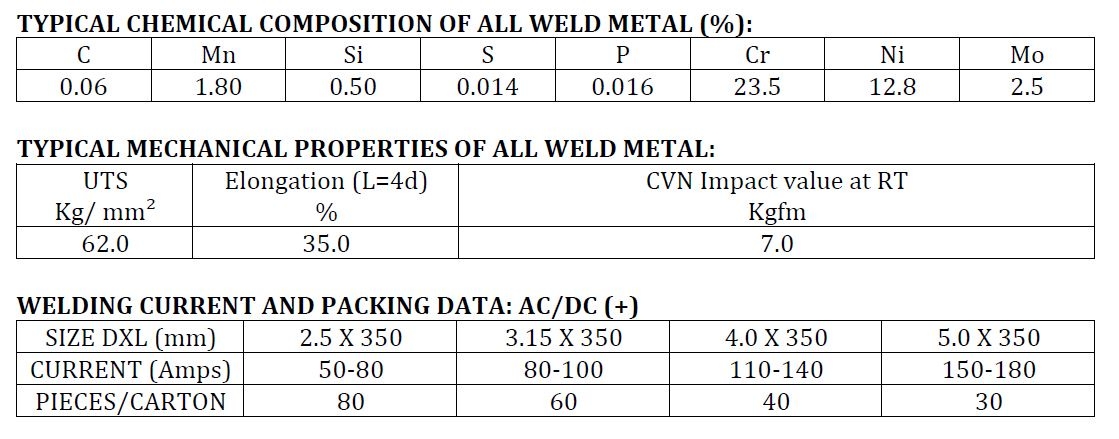

DESCRIPTION AND APPLICATIONS: STEELOMATIC –309 Mo is a rutile type all position electrode depositing Radiographic quality 25 Cr-12 Ni-2.5 Mo weld deposit. Gives a quiet and satiable arc, low spatter, smooth weld use and easily detachable slag. The weld has excellent resistance to corrosion; oxidation resistance is satisfactory up to 1050°C. The electrode is extensively used in dissimilar metal joining between MS and low alloy steels and stainless steels, overlaying and buffering applications, welding straight chrome steels itc.

NOTES ON USAGE:

- Ensure that electrodes are dry enough. In case of moisture pick-up, ready the electrodes at 250°C for 30 to 60 minutes. Thereafter, either allow the oven to cool slowly to about 60° C, or transfer them to a holding oven maintained at 50°C – 60°C.

- Clean the joint faces to remove moisture, grease or any foreign matter.

- Employ welding currents within the prescribed range.

- Keep the arc as short as possible.

- Restrict weaving of electrode to within two and a half times the core wire diameter.

- Use stainless steel wire brush for cleaning the weld beads.

- STEELOMATIC-308

- STEELOMATIC-308 L

- STEELOMATIC-309

- STEELOMATIC-309 L

- STEELOMATIC-309 Mo

- STEELOMATIC-309 Mo L

- STEELOMATIC-309 Mo-15

- STEELOMATIC – 309 Cb

- STEELOMATIC-310

- STEELOMATIC-316

- STEELOMATIC-316 L

- STEELOMATIC-317 L

- STEELOMATIC-318

- STEELOMATIC-318 L

- STEELOMATIC-347

- STEELOMATIC-347 L

- STEELOMATIC – 410

- STEELOMATIC – 430