STEELOMATIC-316 L

STEELOMATIC-316 L

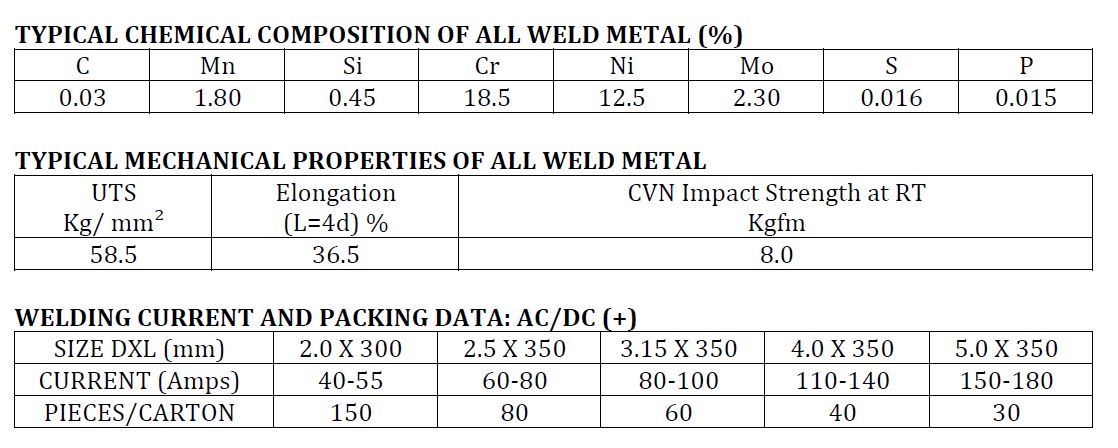

DESCRIPTION AND APPLICATIONS: STEELOMATIC-316 L is a Rutile coated electrode depositing extra low carbon 18Cr-12Ni-2.3 Mo weld metal. The deposit exhibits exceptional corrosion resistance to acids and salts and has very good resistance to pitting attack by chlorides. Intergranular corrosion resistance is excellent, the weld-metal being particularly immune to sensitisation during welding. Ideally suited for welding stainless steel of similar composite.

NOTES ON USAGE:

- Ensure that electrodes are dry enough. In case of moisture pick-up, ready the electrodes at 250°C for 30 to 60 minutes. Thereafter, either allow the oven to cool slowly to about 60° C, or transfer them to a holding oven maintained at 50°C – 60°C.

- Clean the joint faces to remove moisture, grease or any foreign matter.

- Employ welding currents within the prescribed range.

- Keep the arc as short as possible.

- Restrict weaving of electrode to within two and a half times the core wire diameter.

- Use stainless steel wire brush for cleaning the weld beads.

- STEELOMATIC-308

- STEELOMATIC-308 L

- STEELOMATIC-309

- STEELOMATIC-309 L

- STEELOMATIC-309 Mo

- STEELOMATIC-309 Mo L

- STEELOMATIC-309 Mo-15

- STEELOMATIC – 309 Cb

- STEELOMATIC-310

- STEELOMATIC-316

- STEELOMATIC-316 L

- STEELOMATIC-317 L

- STEELOMATIC-318

- STEELOMATIC-318 L

- STEELOMATIC-347

- STEELOMATIC-347 L

- STEELOMATIC – 410

- STEELOMATIC – 430