STEELOMATIC-430

STEELOMATIC-430

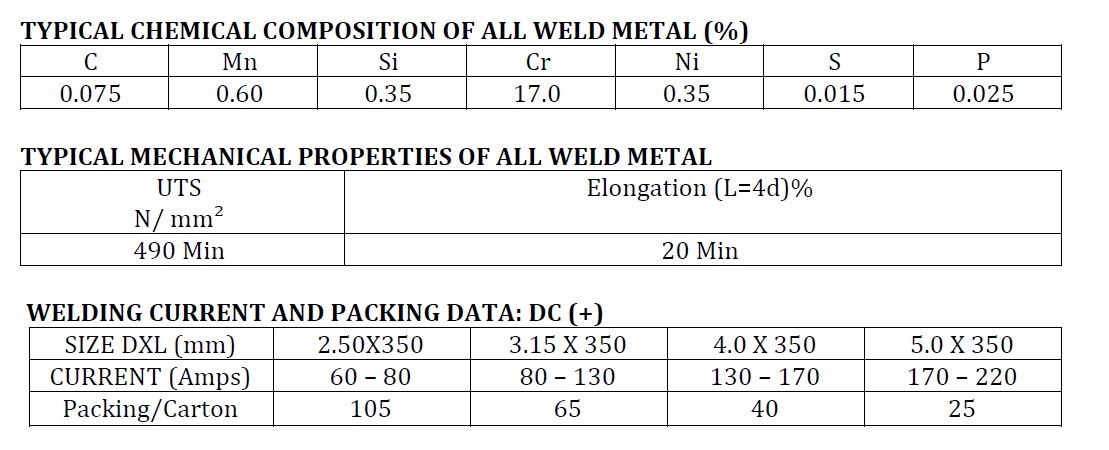

DESCRIPTION AND APPLICATIONS: STEELOMATIC – 430 is a basic type heavy coated all position electrode specially designed for welding 430 type stainless steel and steel containing 17% Cr. It provides weld deposit of 17%Cr, which displays good resistance to corrosion and heat. Typical application include welding of AISI 430 and equivalent steel contain slightly variation in Cr content, surfacing of valves, impellers, turbine blades and valve seats, also suitable for surfacing carbon steel, low alloys steel and chromium steels.

NOTES ON USAGE:

- Ensure that electrodes are dry enough. In case of moisture pick-up, ready the electrodes at 250°C for 30 to 60 minutes. Thereafter, either allow the oven to cool slowly to about 60° C, or transfer them to a holding oven maintained at 50°C – 60°C.

- Clean the joint faces to remove moisture, grease or any foreign matter.

- Employ welding currents within the prescribed range.

- Keep the arc as short as possible.

- Restrict weaving of electrode to within two and a half times the core wire diameter.

- Use stainless steel wire brush for cleaning the weld beads.

- STEELOMATIC-308

- STEELOMATIC-308 L

- STEELOMATIC-309

- STEELOMATIC-309 L

- STEELOMATIC-309 Mo

- STEELOMATIC-309 Mo L

- STEELOMATIC-309 Mo-15

- STEELOMATIC – 309 Cb

- STEELOMATIC-310

- STEELOMATIC-316

- STEELOMATIC-316 L

- STEELOMATIC-317 L

- STEELOMATIC-318

- STEELOMATIC-318 L

- STEELOMATIC-347

- STEELOMATIC-347 L

- STEELOMATIC – 410

- STEELOMATIC – 430